Maximizing Efficiency: Inventory Management Tips

Efficient inventory management is essential for the smooth operation of any warehouse. Without proper inventory control, a warehouse can quickly become chaotic and disorganized, leading to lost items, wasted time, and decreased productivity. However, by implementing some simple tips and tricks, you can maximize efficiency in your inventory management practices and streamline your warehousing operations.

One of the first steps in improving inventory management efficiency is to conduct regular audits of your inventory. By regularly checking your stock levels against your records, you can identify any discrepancies or areas where improvements can be made. This will help you to keep your inventory accurate and up-to-date, reducing the risk of overstocking or running out of essential items.

Another key tip for maximizing efficiency in inventory management is to use technology to your advantage. There are many inventory management software programs available that can help you track your inventory levels, generate reports, and streamline your ordering processes. By investing in the right technology, you can save time and reduce the risk of human error in your inventory management practices.

In addition to using technology, it is also important to establish clear processes and procedures for managing your inventory. By creating standardized workflows for receiving, storing, and picking items, you can minimize the risk of mistakes and ensure that your inventory is always well-organized. This will help you to locate items quickly and efficiently, reducing the time it takes to fulfill orders and improving overall productivity in your warehouse.

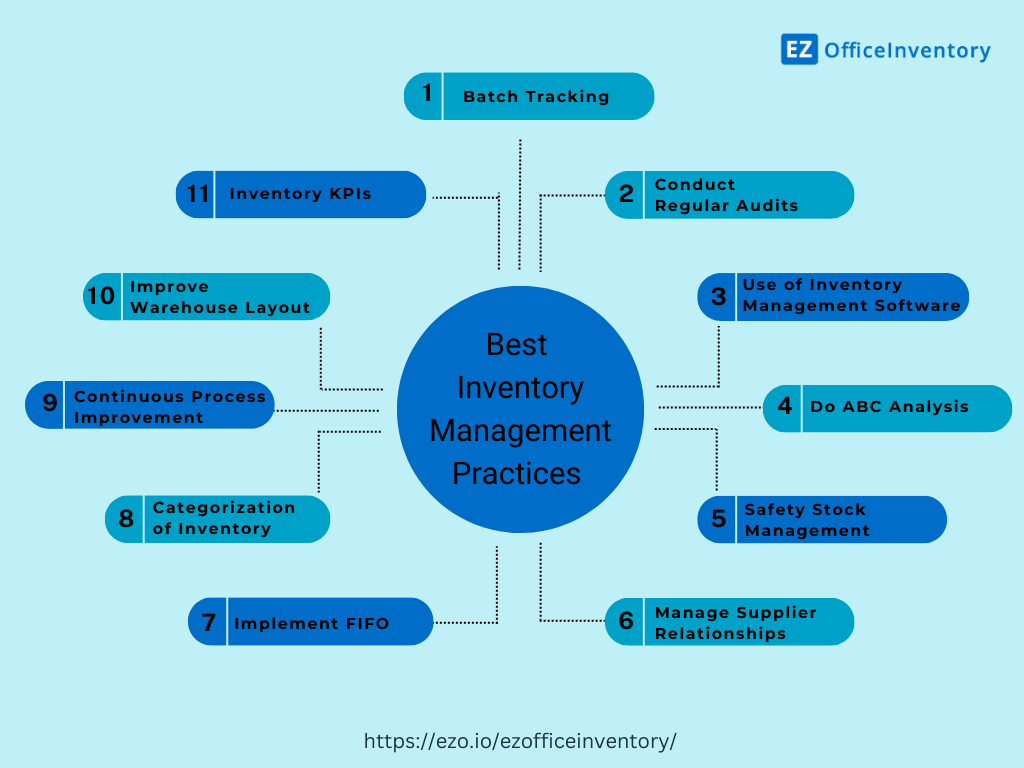

Image Source: ezo.io

Another important tip for maximizing efficiency in inventory management is to prioritize your inventory based on demand. By identifying your best-selling items and placing them in easily accessible locations, you can reduce the time it takes to pick and pack orders, leading to faster turnaround times for your customers. Additionally, by analyzing your sales data regularly, you can adjust your inventory levels to meet changing demand patterns and avoid overstocking slow-moving items.

One often overlooked aspect of efficient inventory management is proper labeling and signage. By clearly labeling each item in your inventory with its location, SKU number, and other pertinent information, you can make it easier for your staff to locate and retrieve items quickly. This can help to reduce the time it takes to fulfill orders and minimize the risk of errors in your inventory management processes.

Lastly, communication is key to maximizing efficiency in inventory management. By keeping your team informed about any changes to your inventory processes, upcoming promotions, or other relevant information, you can ensure that everyone is on the same page and working towards the same goals. Regular meetings and check-ins with your staff can help to identify any areas for improvement and ensure that your inventory management practices are running smoothly.

In conclusion, by following these simple tips and tricks, you can maximize efficiency in your inventory management practices and streamline your warehousing operations. By conducting regular audits, using technology, establishing clear processes and procedures, prioritizing inventory based on demand, implementing proper labeling and signage, and maintaining open communication with your team, you can ensure that your warehouse runs smoothly and efficiently. So, take these tips on board and watch your inventory management practices improve!

Organize and Thrive: Warehousing Inventory Hacks

When it comes to efficient inventory management in warehousing, organization is key. Without a well-organized system in place, warehouses can quickly become chaotic and productivity can suffer. That’s why implementing some clever hacks to streamline your inventory processes can make a world of difference. Here are some top tips to help you organize and thrive in your warehousing operations.

One of the first hacks to consider is implementing a robust categorization system for your inventory. By sorting items into clearly defined categories, you can easily locate and track them when needed. This can be done through the use of barcode systems, color-coding, or even simple labeling techniques. With everything in its rightful place, you’ll save time and effort when searching for specific items, ultimately boosting efficiency in your warehouse.

Another useful hack is to optimize your storage space. Take advantage of vertical space by installing shelving units or mezzanine levels to store items efficiently. This not only maximizes your storage capacity but also allows for better organization and easy access to inventory. Additionally, consider implementing a first in, first out (FIFO) system to ensure that older items are used before newer ones, preventing spoilage or obsolescence.

To further streamline your inventory management, consider investing in technology such as inventory management software. These tools can help automate processes, track inventory levels in real-time, and generate reports for better decision-making. With the right software in place, you can reduce the risk of human error and improve overall accuracy in your warehouse operations.

Another essential hack for efficient inventory management is to conduct regular audits and cycle counts. By regularly checking your inventory levels and comparing them to your records, you can identify discrepancies and address them promptly. This not only helps prevent stockouts or overstock situations but also ensures that your inventory data is accurate and up to date.

In addition to these hacks, it’s important to prioritize safety in your warehousing operations. Ensure that aisles are clear of obstructions, implement proper signage for hazardous materials, and provide training for your staff on safe handling practices. By creating a safe work environment, you can prevent accidents and injuries, ultimately improving productivity and efficiency in your warehouse.

Lastly, don’t underestimate the power of teamwork in your warehouse. Encourage collaboration among your staff members, provide training opportunities for skill development, and foster a positive work culture. By empowering your team and fostering a sense of camaraderie, you can boost morale and motivation, leading to increased productivity and efficiency in your warehousing operations.

In conclusion, organizing your warehouse and implementing these inventory hacks can significantly improve efficiency and productivity in your warehousing operations. By optimizing storage space, utilizing technology, conducting regular audits, prioritizing safety, and promoting teamwork, you can create a well-oiled machine that thrives on organization and efficiency. So, roll up your sleeves, implement these hacks, and watch your warehouse operation flourish.

Best Practices for Inventory Management in Warehousing