Streamlining Your Inventory: A Guide to Efficiency

Are you drowning in excess inventory? Are you constantly struggling to keep track of what you have in stock and what you need to reorder? If so, it’s time to streamline your inventory management process and increase efficiency in your business. By implementing a few simple strategies, you can cut back on excess inventory and save time and money in the long run.

One of the first steps in streamlining your inventory is to conduct a thorough audit of your current stock levels. Take the time to go through each item in your inventory and determine how much you have on hand, how quickly it is selling, and whether or not it is still relevant to your business. By identifying slow-moving items and outdated products, you can make room for new, more profitable items in your inventory.

Next, consider implementing a just-in-time inventory system. This system involves ordering inventory only when it is needed, rather than keeping large quantities on hand at all times. By ordering smaller, more frequent shipments, you can reduce the risk of excess inventory and free up valuable storage space in your warehouse.

Another key strategy for streamlining your inventory is to establish clear reordering criteria. Determine the minimum and maximum stock levels for each item in your inventory, as well as the reorder point at which you need to place a new order. By setting these criteria in advance, you can avoid overstocking on items that are not selling well and ensure that you always have enough stock on hand to meet customer demand.

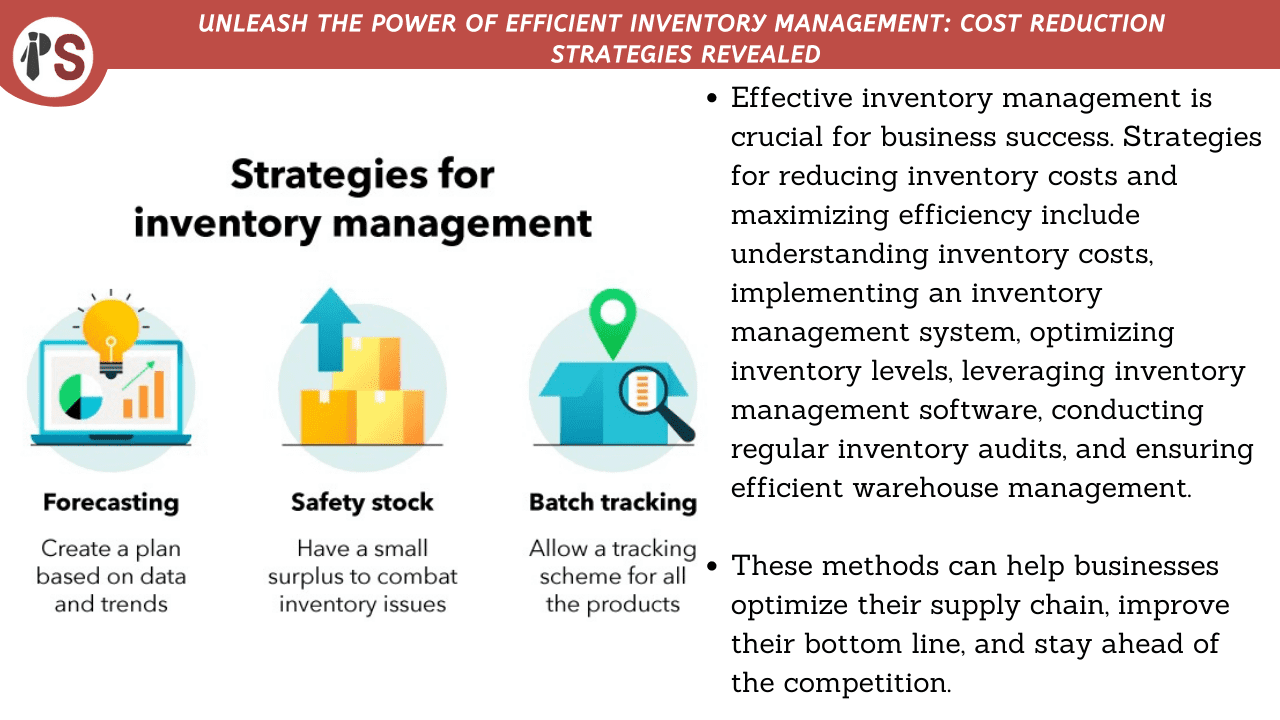

Image Source: professionalsaathi.com

In addition to setting reordering criteria, consider implementing a regular inventory turnover analysis. This involves calculating the rate at which your inventory is being sold and replaced over a specific period of time. By monitoring your inventory turnover rate, you can identify trends in sales and adjust your ordering quantities accordingly.

When it comes to managing your inventory efficiently, technology can be a game-changer. Consider investing in inventory management software that can help you track stock levels, sales data, and reordering needs in real-time. With the right software tools, you can streamline your inventory management process, reduce the risk of human error, and optimize your ordering and stocking processes.

Finally, don’t forget the importance of regular inventory audits. Schedule periodic physical counts of your inventory to ensure that your records are accurate and up-to-date. By conducting regular audits, you can identify discrepancies between your records and your actual stock levels, pinpoint any areas of inefficiency, and make adjustments as needed.

In conclusion, streamlining your inventory is a key step in cutting back on excess inventory and improving efficiency in your business. By conducting regular audits, implementing a just-in-time inventory system, establishing clear reordering criteria, and leveraging technology, you can optimize your inventory management process and save time and money in the long run. So why wait? Start streamlining your inventory today and reap the benefits of a more efficient and profitable business.

Say Goodbye to Excess Stock with Simple Strategies

Excess inventory can be a nightmare for businesses of all sizes. Not only does it tie up valuable resources, but it can also lead to increased storage costs and decreased cash flow. Luckily, there are simple strategies that you can implement to help cut back on excess stock and streamline your inventory management processes.

One of the first steps in reducing excess inventory is to conduct a thorough analysis of your current stock levels. Take a look at your sales data and identify which products are moving quickly and which ones are sitting on the shelves collecting dust. By pinpointing the slow-moving items, you can make more informed purchasing decisions and avoid over-ordering in the future.

Another effective strategy for reducing excess stock is to implement a just-in-time inventory system. This approach involves ordering inventory only when it is needed, rather than keeping a large stockpile on hand. By ordering smaller quantities more frequently, you can reduce the risk of overstocking and free up valuable storage space.

Additionally, consider implementing a vendor-managed inventory system with your suppliers. This approach involves sharing real-time inventory data with your suppliers so that they can help manage your inventory levels. By working closely with your suppliers, you can ensure that you are only ordering the stock you need, when you need it.

Another simple strategy for reducing excess stock is to offer promotions or discounts on slow-moving items. By incentivizing customers to purchase these products, you can help clear out excess inventory and generate additional revenue. Consider running special promotions, such as buy one, get one free, or offering discounts for bulk purchases.

Furthermore, consider implementing a regular inventory rotation schedule. By rotating your stock on a regular basis, you can ensure that older inventory is sold before newer items. This can help prevent products from becoming obsolete and reduce the risk of excess stock accumulating over time.

In addition to these strategies, consider conducting regular inventory audits to identify any discrepancies or inefficiencies in your inventory management processes. By staying vigilant and keeping a close eye on your stock levels, you can proactively address any issues before they escalate into larger problems.

Overall, reducing excess stock requires a combination of strategic planning, data analysis, and proactive management. By implementing simple strategies such as analyzing sales data, implementing just-in-time inventory systems, working closely with suppliers, offering promotions, and conducting regular inventory audits, you can effectively cut back on excess inventory and streamline your inventory management processes. By taking control of your stock levels and implementing these easy tips and techniques, you can say goodbye to excess stock and hello to a more efficient and profitable business.

How to Reduce Excess Inventory: Tips and Techniques