Dive into the World of Just-In-Time Inventory!

Welcome to the exciting world of Just-In-Time (JIT) inventory management! If you’re new to the concept, you’re in for a treat. JIT is a modern approach to inventory management that focuses on minimizing waste and maximizing efficiency. In this beginner’s guide, we will explore the basics of JIT inventory management and how you can get started implementing it in your own business.

So, what exactly is JIT inventory management? At its core, JIT is all about having the right inventory, in the right place, at the right time. This means stocking only what is needed, when it is needed, and in the exact quantity needed. By eliminating excess inventory and reducing lead times, businesses can save money, improve productivity, and respond more quickly to customer demands.

One of the key principles of JIT inventory management is lean manufacturing. This approach emphasizes continuous improvement, waste reduction, and a focus on customer value. By streamlining processes and eliminating non-value-added activities, businesses can operate more efficiently and effectively.

Implementing JIT inventory management may seem daunting at first, but with the right tools and strategies, you can set yourself up for success. Start by analyzing your current inventory levels and identifying areas where you can reduce waste and improve efficiency. Look for ways to streamline your supply chain, minimize lead times, and optimize inventory levels.

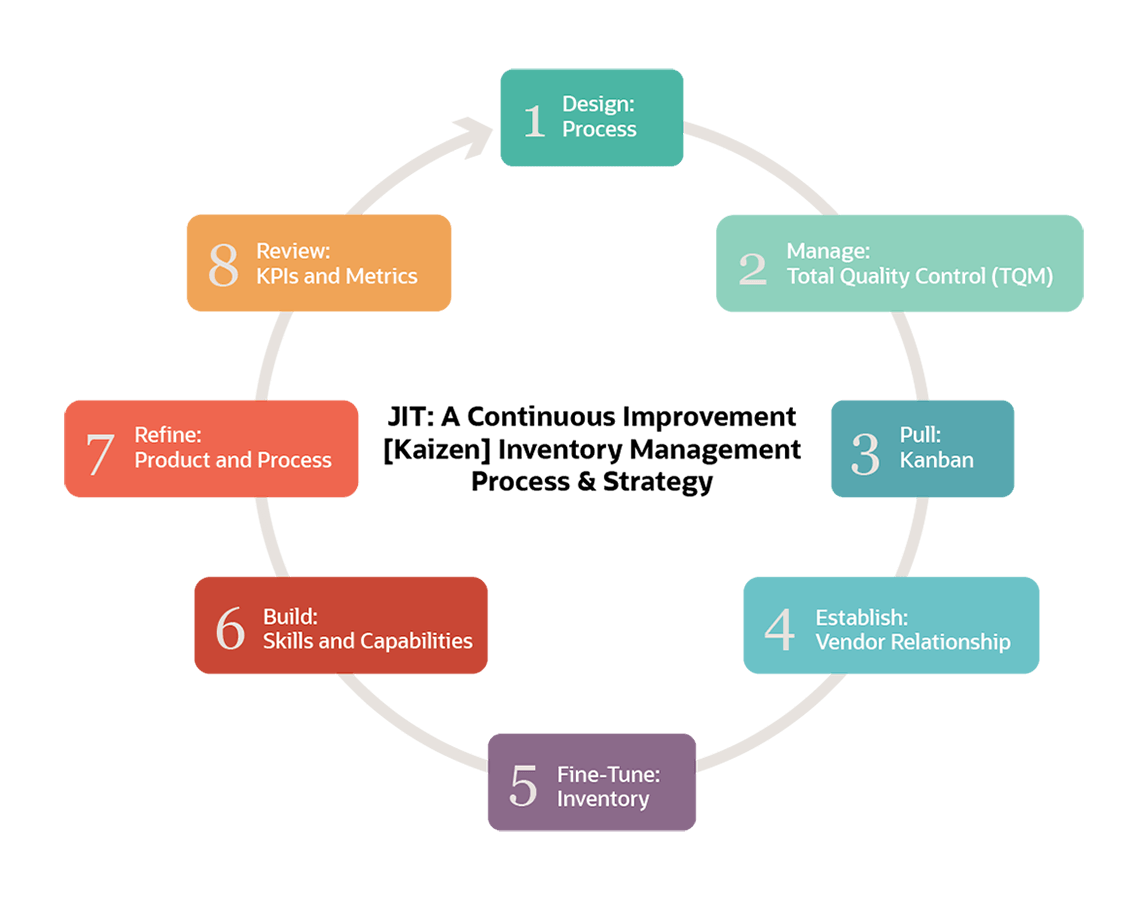

Image Source: netsuite.com

Another important aspect of JIT inventory management is building strong relationships with your suppliers. By working closely with your suppliers and sharing information about demand forecasts and inventory levels, you can ensure a steady supply of materials and reduce the risk of stockouts.

In addition to improving efficiency and reducing waste, JIT inventory management can also help businesses become more responsive to changing market conditions. By maintaining lower inventory levels and implementing flexible production processes, businesses can quickly adapt to fluctuations in demand and market trends.

As you dive deeper into the world of JIT inventory management, you may encounter challenges along the way. From managing inventory levels to coordinating with suppliers, there are many factors to consider. However, with patience, persistence, and a willingness to learn, you can overcome these challenges and reap the benefits of JIT inventory management.

In conclusion, Just-In-Time inventory management is a powerful tool for businesses looking to improve efficiency, reduce waste, and enhance customer satisfaction. By embracing the principles of lean manufacturing and implementing JIT strategies, you can take your inventory management to the next level. So, what are you waiting for? Dive into the world of JIT inventory management today and start reaping the rewards!

Master the Basics with our Beginner’s Guide!

Welcome to the exciting world of Just-In-Time (JIT) inventory management! If you’re new to the concept, don’t worry – we’ve got you covered with our beginner’s guide. In this article, we’ll walk you through the basics of JIT inventory management and help you understand how it can revolutionize your business operations.

First and foremost, let’s start with the basics. Just-In-Time inventory management is a strategy that aims to minimize inventory levels by only ordering or producing goods as they are needed. This means that businesses can reduce costs associated with holding excess inventory, improve cash flow, and increase efficiency in their supply chain.

One of the key principles of JIT inventory management is to eliminate waste. By only producing or ordering what is needed, businesses can avoid excess inventory sitting on shelves, becoming obsolete, or taking up valuable warehouse space. This allows for a more streamlined and efficient operation, ultimately leading to cost savings and increased profitability.

But how exactly does JIT inventory management work? The process begins with forecasting demand and closely monitoring inventory levels. By accurately predicting customer demand, businesses can ensure that they only produce or order the necessary amount of goods. This requires strong communication and collaboration between different departments within the organization, as well as with suppliers and customers.

Another important aspect of JIT inventory management is maintaining strong relationships with suppliers. Since JIT relies on timely delivery of goods, businesses must have reliable suppliers who can meet their production schedules. This means establishing long-term partnerships based on trust, communication, and mutual benefit.

In addition to reducing waste and improving efficiency, JIT inventory management can also lead to faster turnaround times and improved customer satisfaction. By having the right amount of inventory on hand at all times, businesses can respond quickly to customer orders and avoid stockouts. This can help build a loyal customer base and give businesses a competitive edge in the market.

It’s important to note that implementing JIT inventory management is not without its challenges. Businesses must be prepared to invest in technology, training, and process improvements in order to successfully adopt this strategy. Additionally, there is always a risk of supply chain disruptions that can impact production schedules and inventory levels.

Despite these challenges, the benefits of JIT inventory management far outweigh the risks. By mastering the basics of JIT and implementing it effectively in your business, you can achieve cost savings, improve efficiency, and enhance customer satisfaction. So what are you waiting for? Dive into the world of JIT inventory management and take your business to the next level!

A Beginner’s Guide to Just-In-Time Inventory Management